- ISO 9001:2015 Certified Company

Distillation Column Manufacturers in Maharashtra

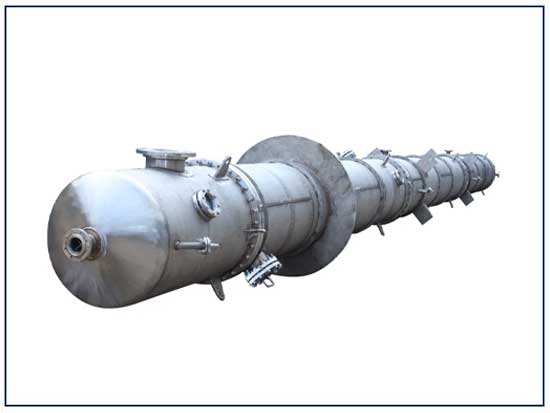

Suyom Engineering Pvt. Ltd. stands out as a reliable name among distillation column manufacturers in Maharashtra, suppliers, and exporters in Maharashtra. With a strong presence in the state, we specialize in delivering advanced solutions for industrial separation processes. Operating from our Maharashtra-based facilities, we are committed to driving production efficiency through cutting-edge innovations. Known by various names such as Industrial Distillation Column, Fractionating Column, and Distillation Tower, our products are designed to meet diverse industry needs across Maharashtra and beyond.

Recognized among the top Distillation Column Manufacturers, Suppliers, and Exporters in Maharashtra, we are proud recipients of the India 5000 Best MSME award (2019), presented by Benchmark Trust in collaboration with TQV as audit partners. Our commitment to excellence is reinforced by our ISO certifications-ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018-ensuring quality in the engineering, production, delivery, and commissioning of industrial process equipment such as a Distillation/Fractionating Column, Distillation Tower and many more. Our services cover industries like specialty food plants, chemicals, turnkey solutions, and pharma for industrial applications of process industries worldwide.

Serving clients across Maharashtra and beyond, our solutions support a broad range of sectors including chemical processing, pharmaceuticals, specialty food industries, and turnkey project execution for industrial applications across the globe.

Overview of the Distillation Column: Specifications, Types, Applications, and How It Works

Distillation is the process of separating a liquid mixture into its component fractions based on differences in boiling points, realized through vaporization and condensation steps. Suyom’s columns are designed per ASME and API standards, ensuring compliance with global safety and quality norms. There are many types of columns like Batch, Continuous, Stripping, Azeotropic, Extractive, Vacuum, and High-Pressure Columns

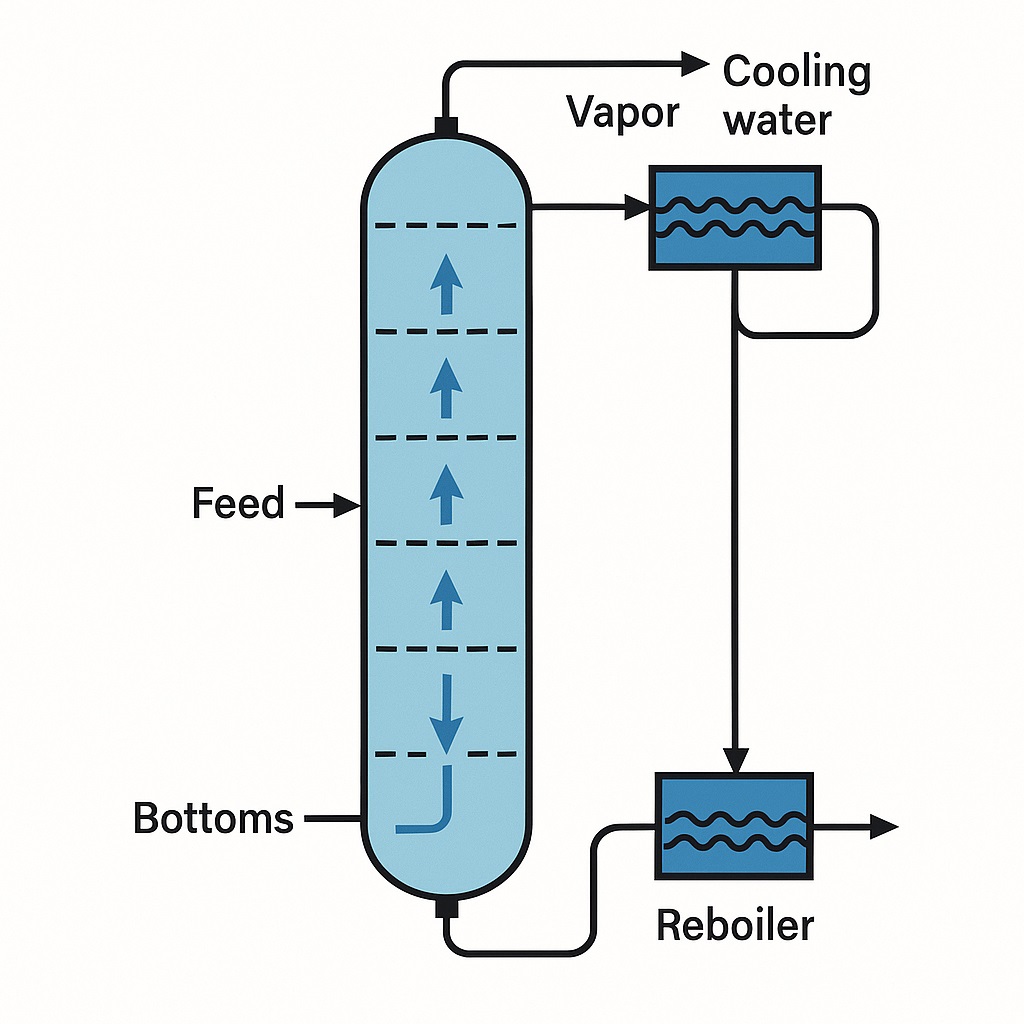

Working Principle: Vapor-liquid equilibrium drives separation: feed is vaporized, components separate by volatility on trays or packing, light fractions ascend, heavy fractions descend, and reflux improves purity

Key Specifications:

- Diameter: 0.65 m to 6 m; Height: 6 m to 60 m (industry range)

- Materials: SS 304/316L, Duplex, Hastelloy; Glass-lined/Teflon coated options for corrosion-resistance

- Internals: Tray (bubble-cap, sieve, valve) or structured/random packing

Applications:

- Petrochemical fractionation and crude oil refining

- Pharma API purification with cGMP-compliant CIP systems

- Food & Beverage (alcohol distillation, flavor recovery)

Distillation Column Manufacturers, Suppliers, Exporters in Maharashtra

Serving a variety of industries, we are experts in Distillation Column Manufacturers in Maharashtra as well as Distillation Column Suppliers, Exporters in Maharashtra. Our columns are predominantly used in large-scale refining, chemical processing, and pharmaceutical plants. With over 6 years of manufacturing and export experience from Pune, Maharashtra, we ensure on-time delivery and global after-sales support.

What Is a Distillation Column?

A distillation column is a vertical container made to use differences in the boiling points of the individual components to separate a liquid mixture into fractions. It meets stringent ASME VIII Div 1 design codes and follows industry best practices for mechanical and process safety.

Specification of the Distillation Column

Below is a detailed specification of our Distillation Column:

| Specification | Details |

|---|---|

| Column Height | 6 m – 60 m |

| Column Diameter | 0.65 m – 6 m |

| Material of Construction | SS 304, SS 316L, Duplex, Hastelloy; Glass-lined / Teflon-coated |

| Internals | Bubble-cap trays; Sieve trays; Valve trays; Structured/random packing |

| Operating Pressure | Vacuum (down to 0.05 bar) to High Pressure (up to 20 bar) |

| Operating Temperature | Ambient to 400 °C |

| Control Systems | PLC/SCADA integration; IoT-enabled Smart Sensors |

Working Principle of a Distillation Column – Explained by Suyom Engineering Pvt. Ltd.

At Suyom Engineering, we carefully consider the foundational ideas of separation science when designing our distillation columns. The difference in boiling points of the parts in a liquid mixture serves as a basis for a distillation column's work.

And this is how the system operates, step by step:

- Distillation Process: Feed mixture is heated, vaporized and condensed in a way that separates constituents based on boiling points.

- Separation Mechanism: The heavy components become condensed and settle down at the bottom, while light components remain in vapour state and are recovered at the top.

- Reflux and Control: Condensed liquid (reflux) is recycled back to the top in oder to enhance separation, while temperature, pressure, and flow rates are automatically controlled for maximum separation and minimum energy consumption.

Why Choose Us for distillation column in Maharashtra?

- Certified Quality: ISO 9001, 14001, 45001 certified manufacturing since 2018.

- Custom Engineering: customized designs using HYSYS and Aspen Plus simulations

- Energy-Efficient: Up to 30 % energy savings through multi-effect and heat integration.

- Smart Monitoring: PLC/SCADA control with predictive maintenance features.

- Global Reach: Proven export track record with clients in Asia, Europe, and the Americas.

Because of these advantages, Suyom Engineering Pvt. Ltd. continues to be Maharashtra's top supplier, manufacturer, and exporter of distillation columns.

Key Features of our Distillation Column

As the top distillation columns manufacturers and suppliers in Maharashtra, we offer the finest quality of distillation columns, including:

- Tactical Design :

- Material Excellence:

- Automation & IoT Integration :

Approach: We apply process simulation software such as HYSYS and Aspen Plus will create unique column structures for each customer. Our professionals analyze varied design options to pinpoint the most suitable and economical design. We also facilitate seamless integration with existing equipment within a plant.

Flexibility: We customize every column to adapt corrosive flammable or hazardous material to the customer's process. This incorporates flexibility in packing size or tray as well as materials compatibility. Future development programs are also set at the design stage.

Build Quality: We build columns using SS 304 SS 316L Duplex Steel Hastelloy and other process-industry-standard alloys based on process needs. Our fabrication is stringently quality-checked to provide strength durability and corrosion resistance. We adopt rigorous welding and testing standards.

Special Coatings: Teflon-coated and glass-lined products are available with us for corrosive or high-purity use. These products increase equipment life and lower maintenance. Surface treatment solutions for extreme operating conditions are also available with us.

Smart Monitoring: We monitor and control performance in real time using SCADA and PLC technologies. This enables our operators to take prompt decisions and ensure product quality round the clock. We construct control logic as a function of process variability to provide stable output.

Predictive Systems: We make use of smart sensors and analytics to predict performance defects and maintenance requirements prior to a catastrophe. Engineers can monitor the column from any location on the planet thanks to remote access technologies.. This optimizes uptime and minimizes unexpected shutdowns.

- Energy Efficiency :

Thermal Optimization: We use multi-effect distillation and energy integration methods to minimize fuel consumption and heat loss. These features provide significant operating cost savings especially in energy-intensive applications. Internally, our fittings are of low-pressure drop and high contact efficiency.

Sustainable Operation: We work towards energy saving of up to 30 percent through the optimization of column internals and heat recovery hardware. This meets the standards of environmental regulations and sustainability. We also provide retrofitting of installed units.

Advantages of Selecting Suyom Distillation Columns

One of the best distillation column suppliers and exporters in Maharashtra, these all types of new distillation column gives various types of advantages such as:

- Product Quality: We ensure high-purity product output through accurate separation methods supported by advanced control systems. Our columns maintain consistent performance even under fluctuating process conditions. We use real-time process analytics to track purity and enhance separation accuracy.

- Operational Reliability: We design each column with durable components and robust construction that ensures longer equipment life and less unplanned downtime. Our systems are designed for tough usages and challenging conditions. We also provide proactive maintenance support to keep operations running smoothly.

- Cost Savings: We reduce operational costs by integrating power-efficient designs and low-maintenance parts. This ensures long-term savings and a high return on investment for our clients. We also support clients in optimizing their existing systems through retrofitting and upgrades.

- Safety Features: We integrate safety systems such as pressure relief valves flame arrestors and leakage monitoring units across all our distillation models. These features guarantee compliance to safety standards and protect your operations. We also offer customized safety enhancements based on process risk assessments.

Applications of our Distillation Column

Our all types of new distillation column are highly demanded from various types of industrial sectors such as:

- Petrochemical & Refining Solutions: High-capacity columns for crude oil fractionation, naphtha treatment, and gasoline blending with thermal integration and energy recovery.

- Pharmaceutical & Fine Chemicals Expertise: Precision separation systems for API production, solvent recovery, and intermediate concentration, compliant with cGMP standards and featuring automated clean-in-place systems.

- Food & Beverage Processing: Gentle separation systems for alcohol distillation, flavour recovery, and food oil deodorization, preserving aroma and nutritional value with food-grade construction and CIP compatibility.

- Technology: Integration of fermentation and distillation in compact modular systems.

- Materials: Bio-compatible materials for better space utilisation and improved process efficiency.

- System Design: Adaptable to evolving biofuel technologies and suitable for decentralised or remote installations.

A Forward-Looking Outlook: What’s Next in Distillation Technology

- We remain at the forefront of distillation innovation as industries embrace smarter cleaner and more adaptive technologies. Our vision is based on a strong belief in sustainable industrial evolution and engineering excellence.

- We make flexible skid-mounted distillation systems that are easy to expand or relocate, have a quicker deployment time, and require less installation time.

- We are building AI-powered systems that forecast process changes in real time and adjust column operations to maintain optimum performance.

- We are investing in green distillation technologies that utilize solar thermal energy and deliver energy-neutral operation with minimal environmental impact.

Distillation Column Ordering, Compliance, and Safety Information

For orders, compliance, and safety certifications:

- Address: Gat No 61, Chimbali Phata, Tal Khed, Pune – 412105, Maharashtra, India

- Phone: +91 9850821742 / +91 7517050101

- Email: sales@suyomengg.com

All equipment is delivered with full PPAP documentation (MTRs, ITPs, FMEA, etc.) and meets ISO 9001:2015, ISO 14001:2015, ISO 45001:2018 standards

Get Distillation Column from Suyom Engineering Pvt. Ltd.

One of the leading distillation column manufacturers, suppliers and exporters in Maharashtra, we as Suyom Engineering specialize in the design and manufacturing of high-performance distillation columns that serve as a backbone for separation processes in various industries. Mixtures are separated based on variations in their boiling points using a vertical vessel known as a distillation column. It plays a key role in refining purifying and recovering valuable components from liquid mixtures in a controlled and efficient manner. For more information, contact us today!