- ISO 9001:2015 Certified Company

Agitator Manufacturers in India

Suyom Engineering Pvt. Ltd., one of the foremost Agitator Manufacturers in India, as well as Agitator Suppliers, Exporters in India, brings over 6 years of proven expertise to your doorstep. Agitator also known as Agitator Mixers, Industrial Agitator. Our agitator units are engineered for uncompromising performance across industries. From pharmaceutical to food processing, specialty chemicals, treatment of effluents, to biotech processes, we are aware of how important proper mixing is. Let us go on a tour of the shapes, characteristics, performance, working mechanism, and new applications of agitators from our technical perspective.

As one of India's top manufacturers, suppliers, and exporters of agitator. Benchmark Trust and Audit Partner TQV awarded us as one of the India 5000 Best MSME awards for 2019. For the design, manufacture, supply, export, and commissioning of process plants and equipment such as agitator design, agitator mixer, INdustrial agitator, etc., we also hold ISO 14001:2015, ISO 45001:2018, and ISO 9001:2015 certifications. Special food plants, chemicals, turnkey solutions, and pharmaceuticals for industrial applications of process industries globally make up the industries we serve.

Overview of the Agitator: Specifications, Types, Applications, and How It Works

Our agitators are built to international standards (ISO 9001:2015, ISO 14001:2015, ISO 45001:2018) using quality-checked stainless steel and exotic alloys. They deliver uniform mixing, precise temperature control, and reliable throughput in tanks and vessels of all sizes.

Key Specifications:

- Material Options: SS304, SS316L, Hastelloy, Duplex.

- Impeller Configurations: Pitched-blade turbines, anchor, propeller, helical ribbon.

- Motor Ratings: IE3 and above, 0.5 kW–150 kW.

- Surface Finish: Up to Ra 0.4 µm for pharmaceutical grade.

- Control Systems: PLC/SCADA/IoT-enabled with predictive maintenance.

Applications:

- Pharmaceuticals: Aseptic blending, homogenization, validation-ready (GMP, ATEX).

- Food & Beverage: Flavor blending, fermentation control (EHEDG-compliant).

- Chemicals & Petrochemicals: Polymerization, slurry processing with corrosion resistance.

- Wastewater Treatment: Efficient pollutant dispersion and aeration.

Agitator Manufacturers, Suppliers & Exporters in India

Founded in 2018 under the tagline "Engineering for Excellence," Suyom Engineering has become a trusted name in high-performance industrial mixing solutions, combining compact design, high accuracy, and low maintenance into every vessel.

We leverage our Agitator Manufacturers in India expertise and Agitator Exporters, Suppliers in India. Network to deliver turnkey solutions nationwide. With over 6 years in the Pune region and beyond, Suyom Engineering Pvt. Ltd. has supplied hundreds of systems-locally and internationally-ensuring timely delivery, on-site commissioning, and after-sales support.

What Is an Agitator?

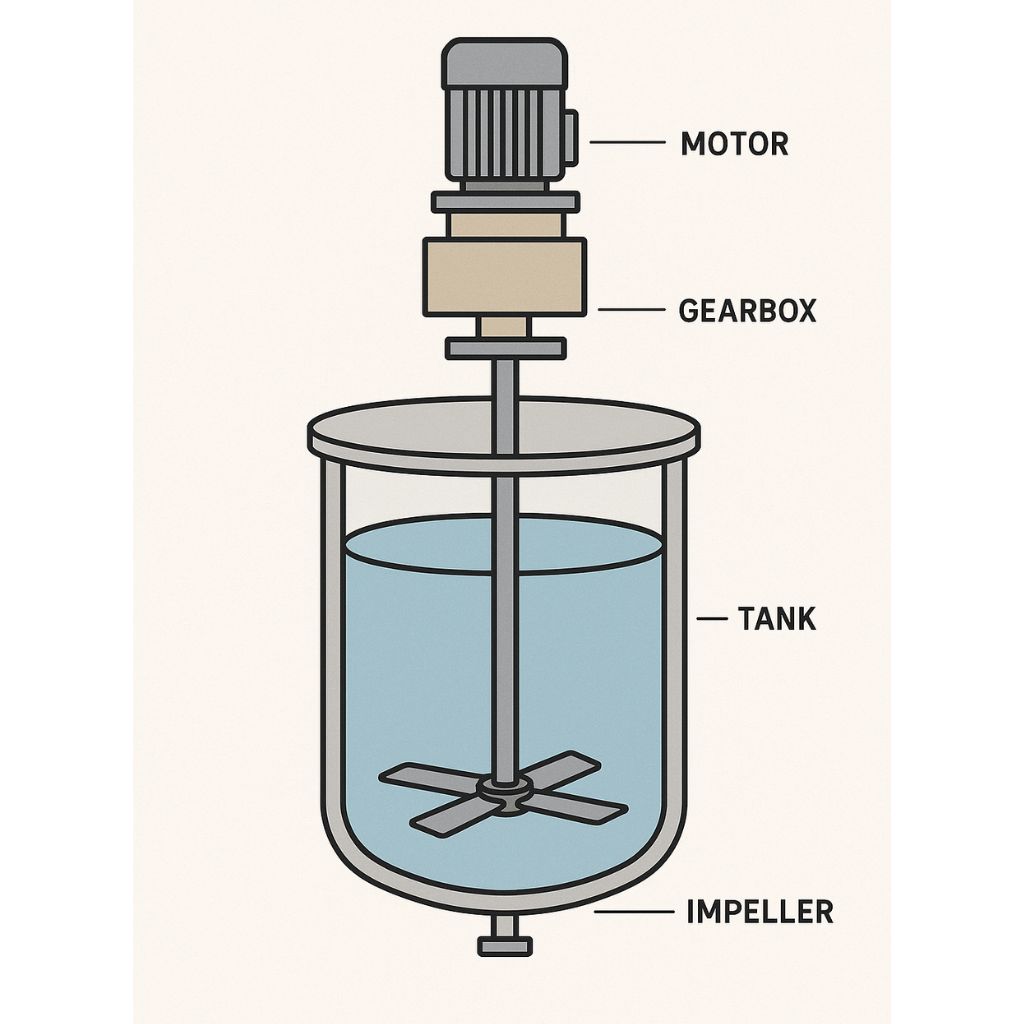

We term an agitator as a mechanical device utilized in the purpose of blending liquids or solids in tanks or vessels to achieve uniform consistency and allow required chemical or physical reactions. It improves the overall product homogeneity keeps temperature evenly and allows blending ingredients better in industrial processing. We manufacture agitators to make your material mixed to the correct specifications every time on every batch.

Specification of the Agitator

Below is a table detailing the general specifications of the agitators offered by Suyom Engineering Pvt. Ltd.:

| Specification | Details |

|---|---|

| Materials | SS304, SS316L, Hastelloy, Duplex |

| Motor Efficiency | Turbine, Anchor, Propeller, Helical, Magnetic |

| Surface Finish (Pharma) | Mirror polish, Ra ≤ 0.4 µm |

| Seal Options | Mechanical seal, magnetic drive, lip seal |

| Control Integration | PLC/SCADA, IoT dashboards, predictive maintenance |

| Design Standards | ASME, GMP, ATEX |

These specifications are indicative and can be customized based on specific process requirements.

Working Principle of Our Agitators

- Mixing Mechanism: Converts mechanical energy from a rotating impeller and shaft to fluid motion, providing complete mixing, homogenization, or reaction enhancement.

- Flow Simulation: Uses CFD software to simulate flow behaviour and guarantee first-run performance.

- Process Efficiency: Offers consistent heat and mass transfer, key to initial process results.

Types of the Agitator

- Propeller Agitator:

- Turbine Agitator:

- Paddle Agitator:

- Anchor (Gate) Agitator:

- Helical (Spiral) Agitator:

Propeller agitators feature marine-type impellers—commonly three-bladed—mounted on a shaft to produce predominantly axial flow with low shear and minimal turbulence. These turbines draw fluid parallel to the shaft and discharge it axially, making them ideal for low-viscosity liquids and high-throughput applications such as water treatment and large-scale solvent mixing.

Turbine agitators consist of multiple flat or pitched blades arranged radially around the shaft. Flat‐blade turbines generate high turbulence and shear through radial discharge, whereas pitched‐blade turbines introduce mixed flow (axial and radial) for enhanced axial pumping and circulation. Their ability to create intense mixing makes them suitable for applications requiring rapid mass or heat transfer, such as chemical reactions and metal extraction processes. Pitched‐blade variants further optimize pumping efficiency, reducing power consumption compared to flat‐blade designs.

Paddle agitators employ large, flat blades extending nearly to the vessel walls, promoting a uniform, laminar flow with gentle mixing and low shear. These are preferred for high-viscosity fluids where minimal shear is required—common in food processing, adhesives, and polymer suspensions—to prevent damage to shear-sensitive materials.

Anchor agitators resemble boat anchors, with blades that sweep the entire vessel wall clearance, ensuring thorough mixing in very viscous media. Variations such as the round anchor and anchor combined with gate feature modified blade geometries for improved wall scraping and reduced dead zones, often used in paints, inks, and resins.

Helical agitators use a continuous spiral ribbon wrapped around a central shaft, creating strong axial flow suitable for mixing highly viscous fluids like food doughs, pastes, and polymer resins. Their design ensures gentle yet effective bulk movement, making them common in the food and polymer industries for consistent product texture.

Important Features of Our Agitators

Being the best agitator suppliers and exporters in India, these all types of new agitators are highly used in various types of applications due to its features such as:

- High-Performance Impeller Designs: We engineer impellers to match a specific flow pattern and mixing needs. From pitched-blade turbines to energy-efficient anchor design, we can fully customize to your process. Our designs are Optimized via Computational Fluid Dynamics to deliver enhanced flow and optimum energy utilization.

- Smart Control Integration: We supply agitators that can be easily interfaced with newer plant control systems such as SCADA PLC or cloud-based IoT. This allows for simple control of mixing speed torque and operation schedules with precise accuracy. Our intelligent systems also enable predictive maintenance by means of system feedback and real-time data.

- Material and Finish Flexibility: We offer a range of materials including SS304 SS316L Hastelloy and other exotic alloys based on your process conditions. Surface finishes are selected to meet hygiene and corrosion-resistance requirements in various industries. For pharmaceutical applications, we offer mirror-polished interior with surface roughness as low as Ra 0.4 µm.

- Energy Optimization: We manufacture agitators featuring IE3-rated or higher efficiency motors to decrease your energy cost. Coupled with flow-optimized impellers our systems realize maximum mixing power at lower energy input. One of our newest designs reduces energy usage by as much as 30 percent against traditional agitators.

Benefits of using our Agitators

Our all types of new technological agitators gives multiple benefits such as:

- Consistency and Repeatability Mixing: Every batch processed through our agitators produces the same result reducing product rejection and loss. Our system allows precise control of blending shear and temperature. This is directly passed on to output quality and decreases production cost per unit.

- Intelligent Operation and Maintenance: Our intelligent systems help you track performance and detect faults before failure. We offer predictive maintenance alerts through the IoT-based dashboards. This reduces surprise downtime and optimizes equipment availability.

- Safety and Compliance: Our agitators are GMP and ATEX ASME certified for sterile as well as explosive applications. Total electricals are explosion-proof certified in case of explosive environments if required. Safe enclosures and duplicated seal mechanisms are supplied in order to safeguard the operator.

Why Should You Buy Our Agitators?

As a dominant agitators exporters in India, these all types of new agitators are highly used in multiple applications such as:

| Industry | Applications | Key Features |

|---|---|---|

| Pharmaceutical | Active ingredient blending, aseptic solution preparation, ointment homogenation | GMP and validation compliant |

| Food and Beverage | Flavour blending, fermentation | EHEDG-graded agitators, maintains flavour consistency and product integrity |

| Chemical and Petrochemical | Resin synthesis, polymerization, emulsion processes | Heavy-duty, corrosive-resistant agitators, resistant to chemicals, heat, and abrasive slurries |

Agitator Ordering, Compliance & Safety Information

For ordering and compliance details, please contact:

- Address: Gat No 61, Chimbali Phata, Chimbali, Tal-Khed, Pune 412105, Maharashtra, India

- Phone: +91 9850821742 / +91 7517050101

- Email: sales@suyomengg.com

- Our agitators comply with: ISO 9001:2015, ISO 14001:2015, ISO 45001:2018, ASME, GMP, and ATEX certifications. All equipment is tested by in-house quality engineers in accordance with our Organization Assessment Plan (OAP).

Why Choose Us for Agitators in India?

- Customized Engineering: Tailored impeller designs and materials to suit your exact process needs.

- Smart Integration: Full PLC/SCADA/IoT compatibility for predictive maintenance and data analytics.

- Global Certifications: ISO and ASME approvals that validate our commitment to safety and quality.

- Experienced Team: 6 years of delivering turnkey solutions across specialty chemicals, pharma, food, and more.

- After-Sales Support: Dedicated service engineers and on-site commissioning for smooth startup.

Together, these strengths make Suyom Engineering your preferred Agitator Manufacturers in India and Agitator Exporters in India.

Because of these advantages, we at Suyom Engineering Pvt. Ltd. stand out as leading Agitator Manufacturers in India and Agitator Suppliers in India.

Looking Ahead: Future-Ready Agitator Solutions

As we are moving towards an era of intelligent manufacturing, we are adding IoT and AI to our agitators. Our systems of the future will come equipped with auto-diagnosis, adaptive speed, and digital twin capabilities. We are at the pilot stage of next-generation agitators, which can adapt in real-time to varying load and viscosity of the product.

One of the top agitator manufacturers, suppliers and exporters in India, we as Suyom Engineering Pvt. Ltd. strive to deliver agitator solutions with consistent performance and process efficiency. We design every system to match changing industry demands through innovative design and good engineering. We offer mission-critical applications like pharmaceuticals chemicals and food with specifically designed agitators that match precise process goals. We design machines not just machines but long-term value that guarantees smooth and reliable operation. For more information, contact us today!