- ISO 9001:2015 Certified Company

Distillation Column Manufacturers in Gujarat

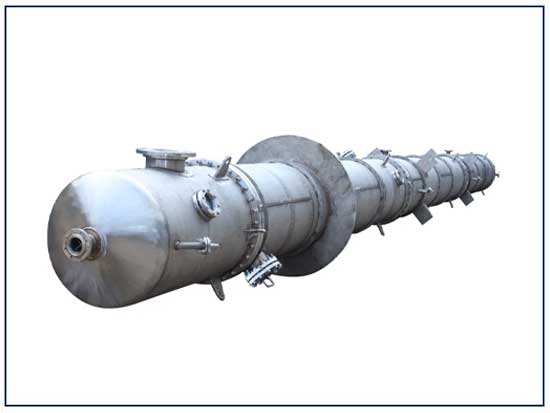

Suyom Engineering Pvt. Ltd. specializes in Distillation Column Manufacturers in Gujarat. Distillation Column also known as a distillation tower or a fractionation column, our solutions are recognized among Distillation Column Suppliers and Exporters in Ahmedabad, Gujarat. With 6+ years of experience in the Chemical Process Equipment Engineering Industry, you can trust us to deliver reliable, high performance distillation systems.

Distillation columns separate mixtures into their component fractions using controlled temperature and pressure. They play a critical role in petrochemical, pharmaceutical, and specialty chemical plants by delivering precise purity and yield.

Visit now to get detailed information about Process Plant Equipment Design Service.

Distillation Column Suppliers and Exporters in Ahmedabad, Gujarat

Suyom Engineering Pvt. Ltd., As leading manufacturers, suppliers and exporters, we excel in custom designing distillation towers that optimize product recovery and energy efficiency. Our columns serve applications such as solvent recovery, fractionation of crude intermediates, and chemical purification. To date, we have partnered with over 150 clients across India and abroad. Contact us today as your leading Distillation Column Manufacturers in Gujarat, and Distillation Column Exporters and Suppliers in Gujarat.

What is a Distillation Column?

A distillation column is a tall, vertical vessel that separates liquid mixtures into fractions based on boiling point differences.

- Product Standard Certification: Our columns meet ISO 9001:2015 for quality management, ASME Section VIII “U” Stamp for pressure vessels, and PED (2014/68/EU) for CE marking.

- Safety Certification: We adhere to ISO 45001 for occupational health and safety and implement IEC 61511 functional safety standards. These certifications ensure safe, compliant, and reliable operations.

Specification of the Distillation Column

| Specification | Details |

|---|---|

| Column Height | 6 m – 60 m |

| Column Diameter | 0.65 m – 6 m |

| Material of Construction | SS 304, SS 316L, Duplex, Hastelloy; Glass-lined / Teflon-coated |

| Internals | Bubble-cap trays; Sieve trays; Valve trays; Structured/random packing |

| Operating Pressure | Vacuum (down to 0.05 bar) to High Pressure (up to 20 bar) |

| Operating Temperature | Ambient to 400 °C |

| Control Systems | PLC/SCADA integration; IoT-enabled Smart Sensors |

Types of Distillation Column

- Batch Distillation Columns: Batch distillation columns shine in small scale or multi product operations. Initially, operators load a fixed quantity of feed. Next, heat is applied to vaporize lighter components. Then, vapors rise through trays or packing. Subsequently, condensers capture and return heavier fractions as reflux. Finally, the desired distillate is collected in batches. Moreover, batch columns offer superior flexibility. You can quickly switch between different feedstocks. However, each batch requires downtime for cleaning and reloading. Consequently, maintenance schedules and turnaround times must be carefully planned. Therefore, batch distillation columns are perfect when product variety matters more than continuous output.

- Continuous Distillation Columns: Continuous distillation columns excel in high volume, steady state processes. First, feed enters the column without interruption. Then, a reboiler provides constant vapor flow. Meanwhile, lighter components ascend while heavier ones descend. As a result, product purity remains consistent around the clock. Additionally, continuous columns maximize throughput. They eliminate the need for frequent shutdowns. Furthermore, automated control systems ensure precise temperature and pressure profiles. Thus, they deliver reliable performance and energy efficiency. In short, continuous distillation columns are the go to choice for large scale industrial separation.

Applications of the Distillation Column

- Petrochemical Refining: Fractionation of crude intermediates into naphtha, gasoline, and heavy residues.

- Pharmaceutical Production: Purification of solvents and active pharmaceutical ingredients to meet stringent purity standards.

- Chemical Manufacturing: Separation of specialty chemicals, enabling high value compound recovery.

- Food & Beverage: Alcohol fractionation and essential oil recovery with controlled flavor profiles.

- Environmental: Solvent recovery and waste minimization in industrial effluents.

How It Works

Distillation relies on repeated vaporization and condensation cycles. Feed enters the column, vapor rises through trays or packing, and lighter components ascend to the top. Heavier fractions descend and are withdrawn at various points. Reboilers supply heat at the base, while condensers at the top cool and return liquid to maintain equilibrium.

Distillation Column Ordering, Compliance, and Safety Information

When ordering, specify required capacity, material, and internals. We ensure compliance with ASME, API, PED, EN, and local regulations. For safe operation, our engineers conduct on site inspections, provide detailed PPAP documentation—including Material Test Reports, Inspection Test Plans, and FMEA—and offer operator training.

- Address: Gat No 61, Chimbali Phata, Tal Khed, Pune – 412105, Maharashtra, India

- Phone: +91 7517050101

- Email: sales@suyomengg.com

Why Choose Us?

- Proven Expertise: Over 6 years in custom process equipment design and manufacturing.

- Quality Driven: ISO 9001, ASME “U”/“U2”, API, TEMA, and NACE certifications.

- Innovative Solutions: Compact designs, IoT enabled controls, and energy recovery options.

- Minimal Maintenance: Robust construction with corrosion resistant alloys.

- Ethical Partnerships: Transparent vendor vetting and comprehensive PPAP documentation.

Because of these strengths, Suyom Engineering Pvt. Ltd. remains your first choice among Distillation Column Manufacturers in Gujarat, Distillation Column Exporters and Suppliers in Gujarat.

Get Distillation Column in Gujarat | Suyom Engineering Pvt. Ltd.

Suyom Engineering Pvt. Ltd. is a trusted manufacturer in Gujarat, as well as a leading supplier and exporter. We excel in delivering turnkey distillation column solutions tailored to your process needs.

Ready to optimize your separation processes? Request a Quote or Contact Sales today at +91 7517050101 or sales@suyomengg.com.

Related Serches: Distillation Column Manufacturers in Gujarat, Distillation Column Suppliers in Gujarat, Distillation Column Exporters in Gujarat, Distillation Column Manufacturers in Ahmedabad, Distillation Column Suppliers in Ahmedabad, Distillation Column Exporters in Ahmedabad, Distillation Column Manufacturers, Distillation Column Suppliers, Distillation Column Exporters, Distillation Tower Manufacturers in Gujarat, Distillation Tower Suppliers in Gujarat, Distillation Tower Exporters in Gujarat, Distillation Tower Manufacturers in Ahmedabad, Distillation Tower Suppliers in Ahmedabad, Distillation Tower Exporters in Ahmedabad, Distillation Tower Manufacturers, Distillation Tower Suppliers, Distillation Tower Exporters, Fractionation Column Manufacturers in Gujarat, Fractionation Column Suppliers in Gujarat, Fractionation Column Exporters in Gujarat, Fractionation Column Manufacturers in Ahmedabad, Fractionation Column Suppliers in Ahmedabad, Fractionation Column Exporters in Ahmedabad, Fractionation Column Manufacturers, Fractionation Column Suppliers, Fractionation Column Exporters, Batch Distillation Column Manufacturers in Gujarat, Batch Distillation Column Suppliers in Gujarat, Batch Distillation Column Exporters in Gujarat, Batch Distillation Column Manufacturers in Ahmedabad, Batch Distillation Column Suppliers in Ahmedabad, Batch Distillation Column Exporters in Ahmedabad, Batch Distillation Column Manufacturers, Batch Distillation Column Suppliers, Batch Distillation Column Exporters, Continuous Distillation Column Manufacturers in Gujarat, Continuous Distillation Column Suppliers in Gujarat, Continuous Distillation Column Exporters in Gujarat, Continuous Distillation Column Manufacturers in Ahmedabad, Continuous Distillation Column Suppliers in Ahmedabad, Continuous Distillation Column Exporters in Ahmedabad, Continuous Distillation Column Manufacturers, Continuous Distillation Column Suppliers, Continuous Distillation Column Exporters, Distillation Column Manufacturers near me in Gandhinagar-Gujarat, Distillation Column Manufacturers in Gandhinagar Sector 21, Distillation Column Manufacturers in Kudasan, Distillation Column Manufacturers in Gandhinagar Sector 16, Distillation Column Manufacturers in Gandhinagar Sector 7, Distillation Column Manufacturers in Sargasan, Distillation Column Manufacturers in Gandhinagar Sector 22, Distillation Column Manufacturers in Gandhinagar Sector 11, Distillation Column Manufacturers in Chhatral GIDC, Distillation Column Manufacturers in Mansa, Distillation Column Manufacturers in Adalaj, Distillation Column Manufacturers in Chiloda Gandhi Nagar, Distillation Column Manufacturers in Chhatral, Distillation Column Manufacturers in Gandhinagar Sector 2, Distillation Column Manufacturers in Gandhinagar Sector 24, Distillation Column Manufacturers in Gandhinagar Sector 26.